Number 14.

Work in Progress. Benches.

Number 13.

32 test pieces of porcelain ready to be fired. Each is uniquely marked so that I can record the application of glaze and other chemicals as well as temperature experimentation to identify the effects on the finished body.

Number 12.

Powder coated scaffolding joint and nut

Number 11.

White ABS printed using 3dhubs which is 3d printing space that connects designers to printers. I drew my file up using Rhino and then converted it to an .STL before sending to a hub in Borehamwood which could produce in the material I required. This is to be used as a master in making a cast so it needed to be strong enough to withstand silicon rubber and plaster.

Number 10.

Triangular and Octagonal iterations.

Number 9.

'Tetrapods are designed in such a way that they dissipate the force of incoming waves by making the water flow around rather than against them... A number of tetrapods arranged together form an interlocking, porous barrier that dissipates the power of waves and currents...The main feature of the tetrapod lies in its design which is not found in nature. Tetrapods are a symbol of artificiality rather than aesthetics'

Number 8.

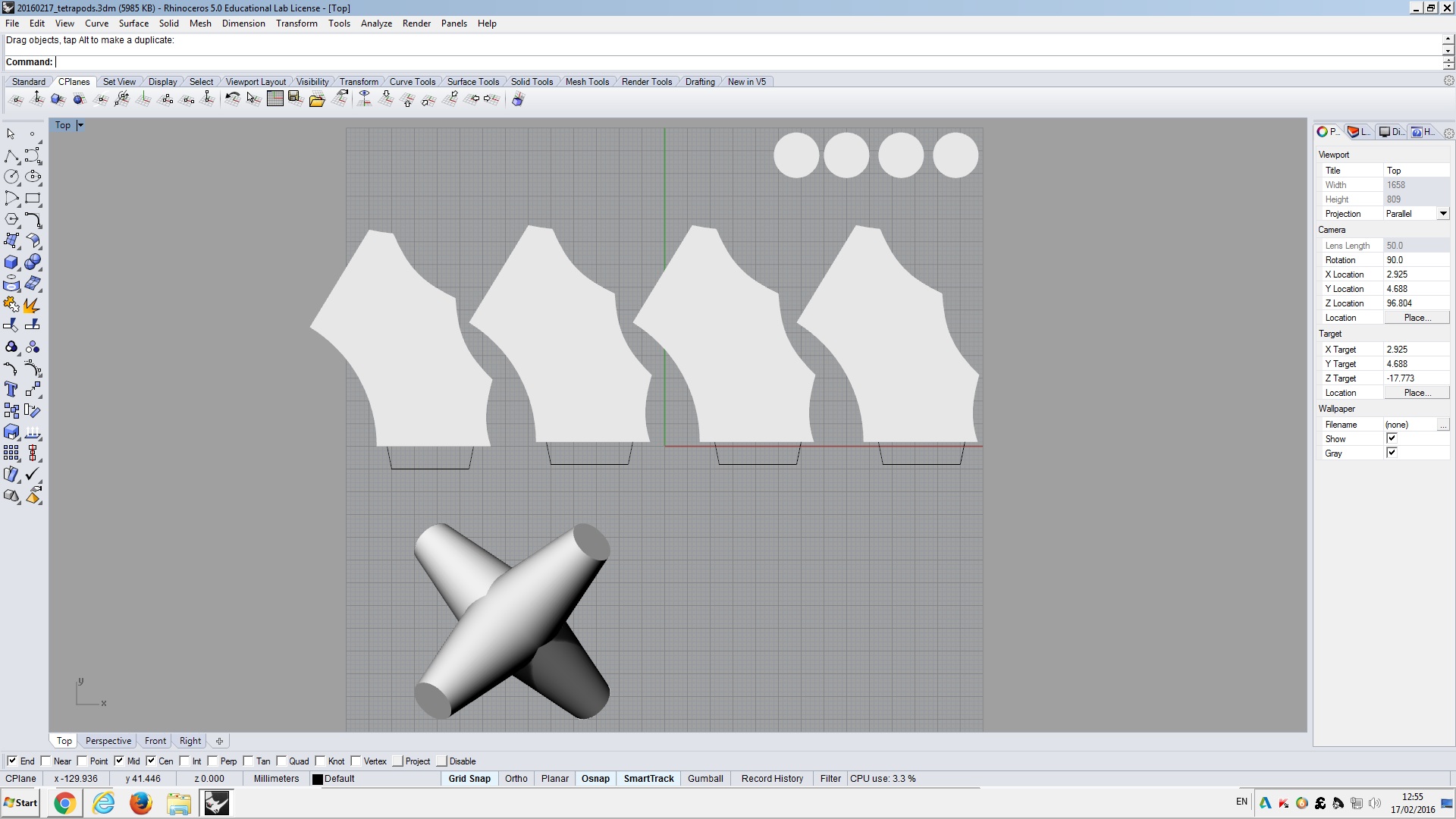

Tetrapod, solid and unwrapped. Ready for printing and casting.

Number 7.

Scaffolding netting jointed dowels. Melted with a heat gun.

Number 6.

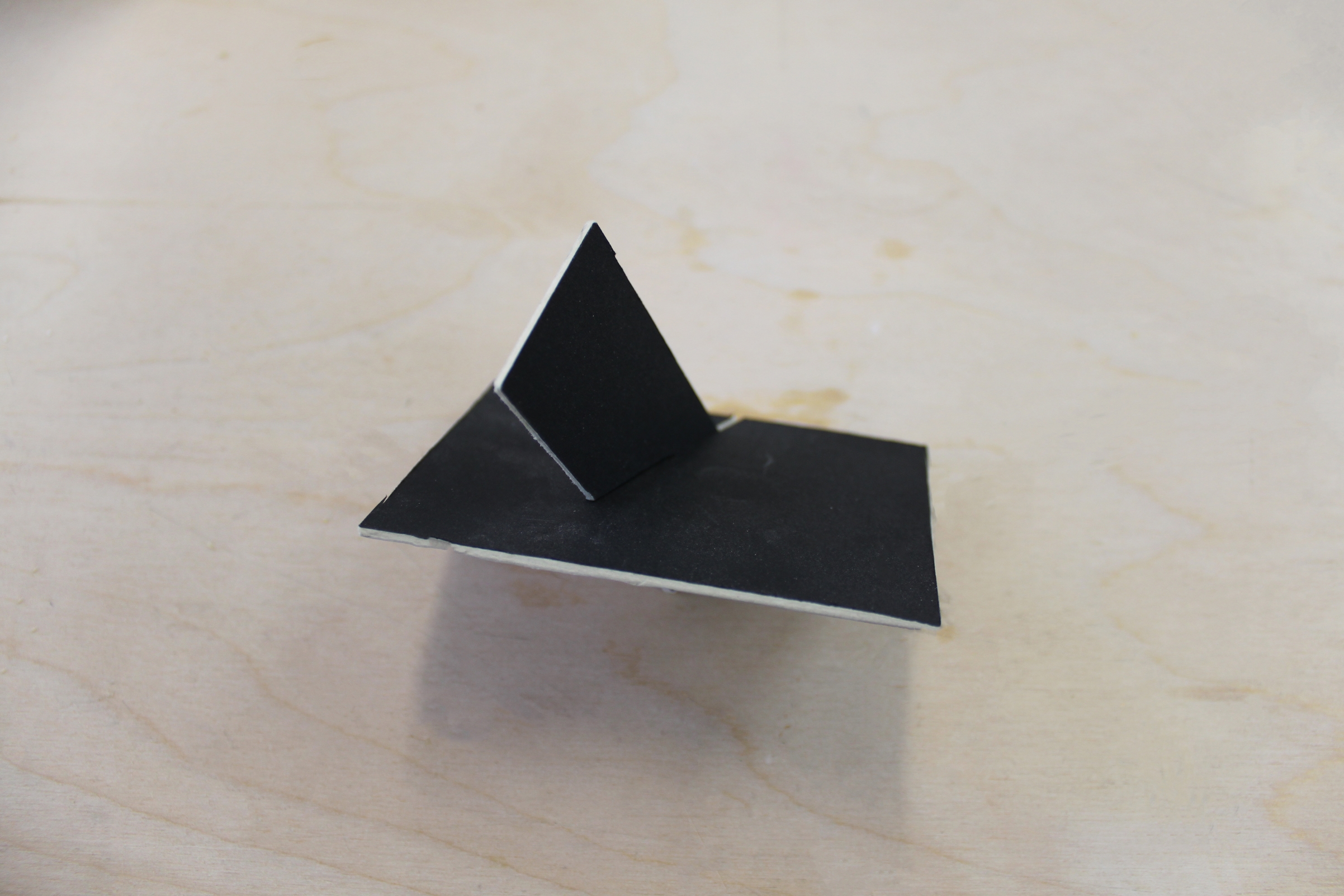

Interlocking card structure with multiple heights depending on rotation.

Number 5.

Plaster and Clay from below.